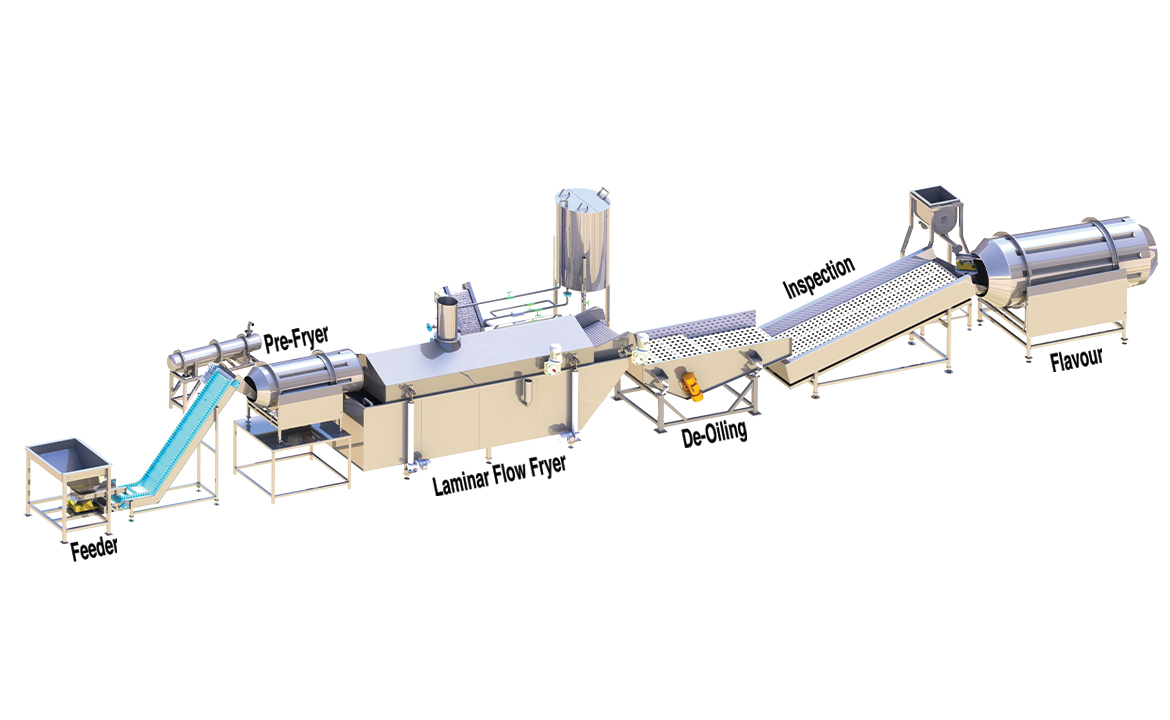

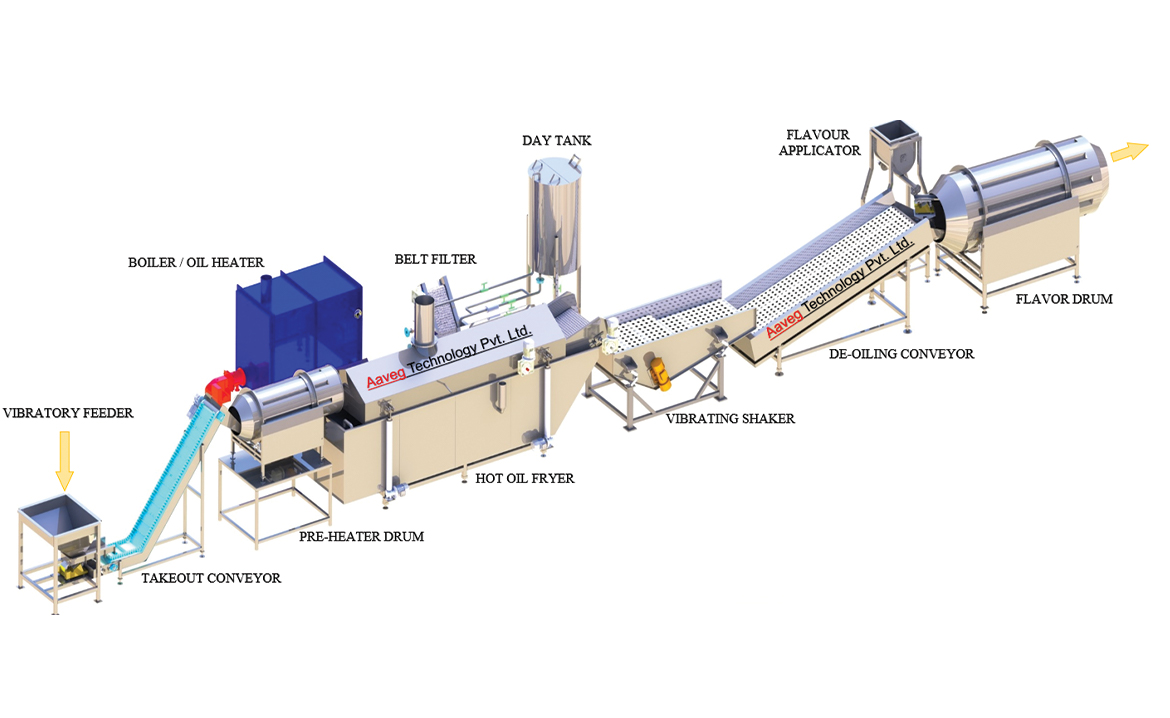

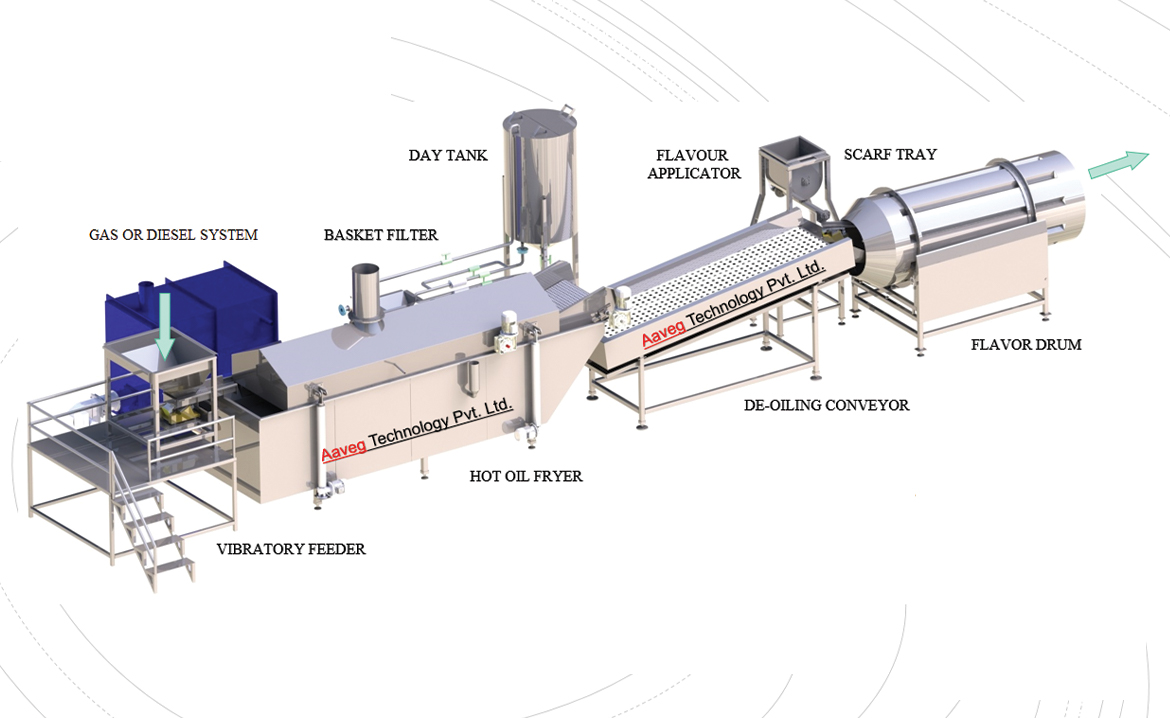

snack pellet process line

Pellet Frying Line 500 Kg/Hr

Pellet Frying Line 300 Kg/Hr

Description

- ● Hopper with digital control feeding.

- ● Pre-fryer for Extra moisture.

-

● De-oiling Vibrating Shaker.

- Approximately 3% oil saving.

- Based on Amplitude design.

- Double deck conveyor.

- Imported vibrating motor.

- Vibration less supporting stand.

- Automatic oil return. -

● Inspection & Cooling Conveyor.

- Imported SS 304 wire-mesh belt.

- Variable Air cooling.

- Provision of belt cleaning by Air. -

● Flavour Equipments.

- Flavour mixture & feeder.

- Fine flavour spray tray.

- Typical design flighted drum for uniform flavouring. -

● Electrical & Automation panel.

- European standard.

- Easy to operate, easy to maintain.

- Human friendly working with Safety. -

● Laminar Flow FRYER.

- European design.

- Multiple oil inlet.

- Uniform temperature throughout fryer tank.

- Imported wire-mesh belt.

- Digital control speed.

- Auto control of oil level in system.

- Lowest oil holding capacity.

- Fast changeover of oil from tank.

- Fine filtration of running oil.

- Easy maintenance.

- Shower assembly for cleaning of belt & fryer.